About Us

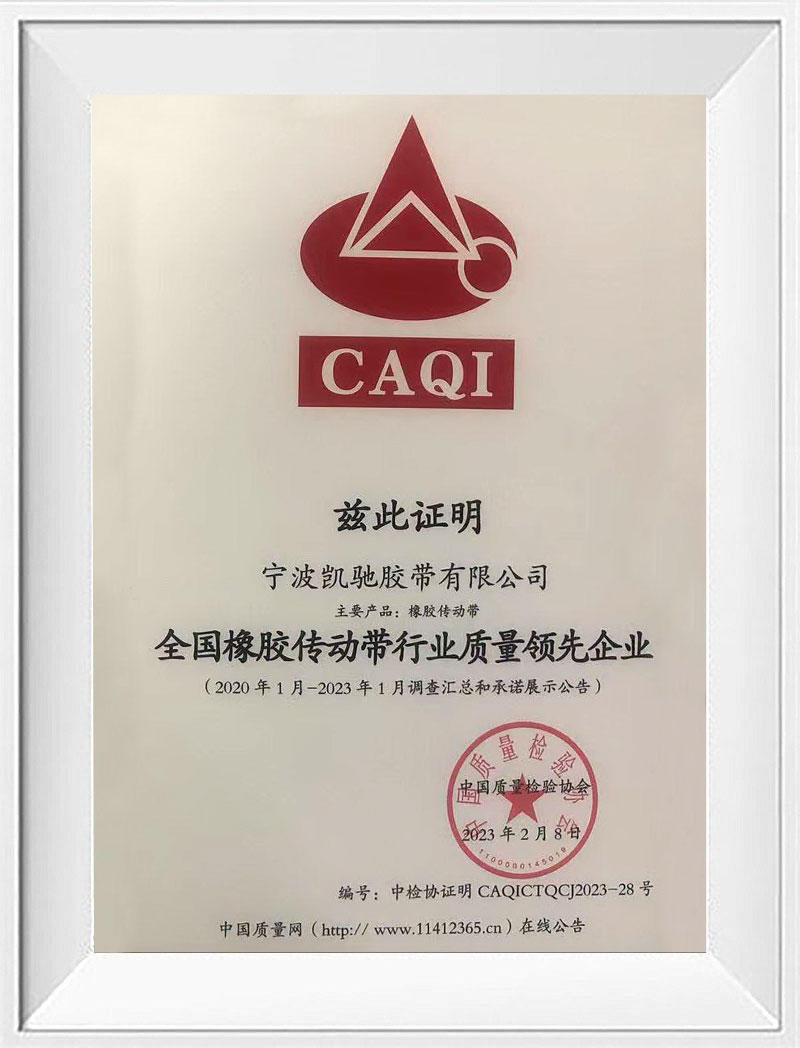

Honor

Pay attention to news News and Exhibitions

-

How does the installation angle of a ribbed belt affect its performance

As a transmission device commonly used for power transmission, ribbed belts are widely used in many fields such as industry, automobiles, and home app...Explore More -

How does the tensile strength of a ribbed belt affect its service life

Ribbed belts, as an important component in modern mechanical transmission systems, are widely used in automobiles, industrial equipment, household app...Explore More -

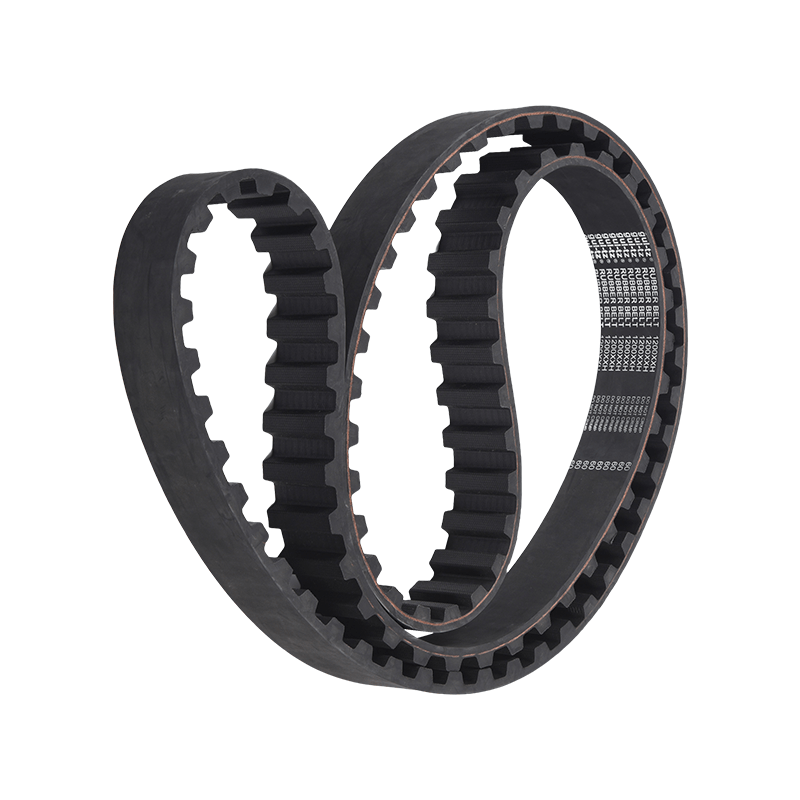

What are the advantages and disadvantages of arc-tooth synchronization belts compared with chain transmission

In mechanical transmission systems, arc-tooth synchronous belt and chain transmission are two common and important power transmission methods. The two...Explore More -

How much does the arc design of the synchronous belt tooth shape affect the meshing stability

As an important power transmission element in modern mechanical transmission systems, the performance of the synchronization belt is directly related ...Explore More -

How does the tooth design of synchronous timing belts affect its performance

Tooth design plays a vital role in the performance of synchronous belts, directly affecting their synchronization accuracy and transmission efficiency...Explore More

Industry knowledge about Pulley

What are the key factors to consider when selecting belt pulleys materials?

In modern mechanical transmission systems, the selection of pulleys has an important impact on the overall performance and stability of the system. Especially when selecting pulley materials, factors such as the mechanical properties, wear resistance, corrosion resistance and environmental adaptability of the materials need to be fully considered. Since its establishment in 1992, Ningbo GUL TZ Rubber Belt Co., Ltd. has focused on the research and development and production of rubber timing belts, V-belts, open belts and timing pulleys. As a national high-tech enterprise, the company has accumulated rich experience in material selection and product design.

In the design of pulleys, mechanical properties are the primary consideration for material selection. Mechanical properties include tensile strength, compressive strength, hardness and toughness. These properties directly determine the ability of pulleys to withstand loads during operation. Taking rubber materials as an example, they have good elasticity and vibration resistance, so they are very suitable for applications where shock absorption is required. Metal materials, such as aluminum alloys or steel, are usually used in transmission systems that carry high loads and high speeds due to their high rigidity and wear resistance. Ningbo GUL TZ Rubber Belt Co., Ltd. has selected rubber materials through rigorous mechanical property tests to ensure that they can maintain excellent performance under various working conditions, which is essential to ensure the long-term stability and reliability of the product.

Wear resistance is another key indicator for the selection of pulley materials. During the working process, the friction between the pulley and the belt will cause wear. If the wear resistance of the material is insufficient, it will directly affect the service life of the pulley and the overall efficiency of the transmission system. Therefore, when selecting materials, its wear resistance must be fully considered. At the same time, corrosion resistance is also a factor that cannot be ignored. In special industrial environments such as chemical plants and food processing plants, the risk of chemical corrosion is high. Choosing corrosion-resistant materials can effectively extend the service life of the pulley and reduce maintenance costs. Ningbo GUL TZ Rubber Belt Co., Ltd. fully considers the needs of different application environments in the process of material selection to ensure that its products can operate stably in a variety of environments.

In addition, the operating temperature range of the pulley is also an important consideration for material selection. The performance of different materials in high or low temperature environments varies significantly. For example, some rubber materials may soften under high temperature conditions, resulting in reduced transmission efficiency and even possible failure. Metal materials may become brittle and prone to breakage in low temperature environments. Therefore, understanding the operating temperature range of the pulley in actual applications and selecting the right material are key to ensuring the normal operation of the pulley.

Environmental factors also affect the choice of materials, such as humidity, dust and the presence of chemicals. In high humidity environments, some materials may absorb water, resulting in reduced performance. To meet these challenges, Ningbo GUL TZ Rubber Belt Co., Ltd.'s products undergo rigorous environmental adaptability testing to ensure that they can maintain excellent performance under a variety of complex environmental conditions.

English

English 简体中文

简体中文