About Us

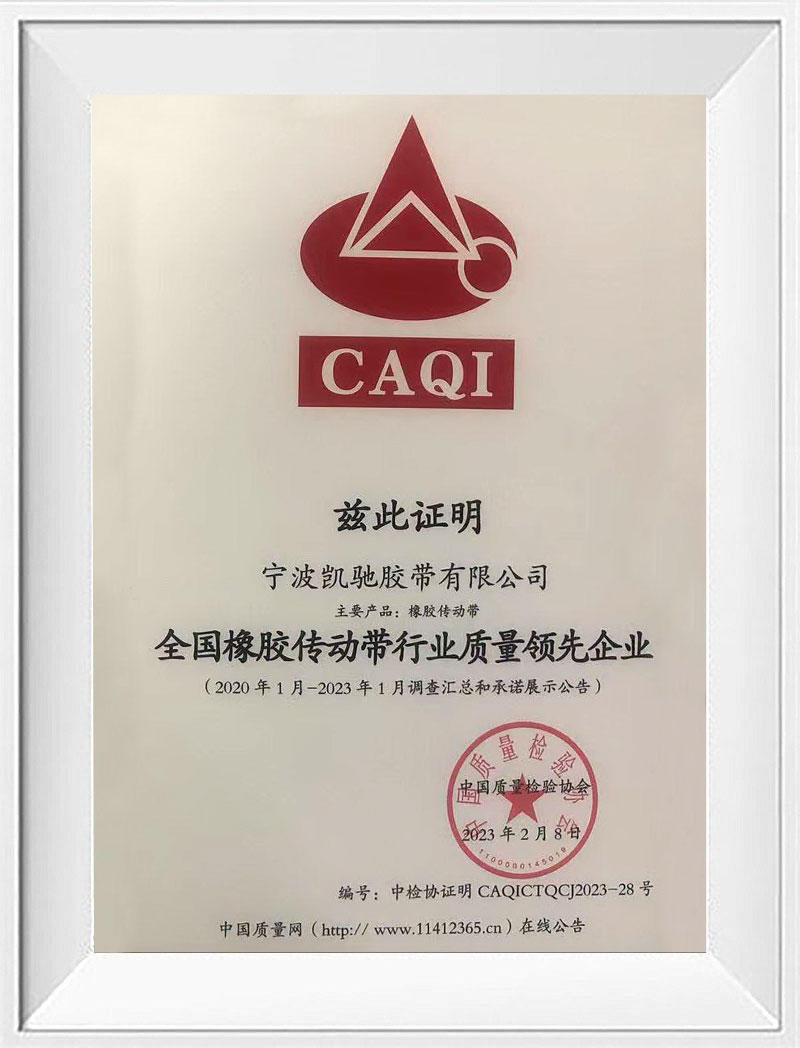

Honor

Pay attention to news News and Exhibitions

-

How does the installation angle of a ribbed belt affect its performance

As a transmission device commonly used for power transmission, ribbed belts are widely used in many fields such as industry, automobiles, and home app...Explore More -

How does the tensile strength of a ribbed belt affect its service life

Ribbed belts, as an important component in modern mechanical transmission systems, are widely used in automobiles, industrial equipment, household app...Explore More -

What are the advantages and disadvantages of arc-tooth synchronization belts compared with chain transmission

In mechanical transmission systems, arc-tooth synchronous belt and chain transmission are two common and important power transmission methods. The two...Explore More -

How much does the arc design of the synchronous belt tooth shape affect the meshing stability

As an important power transmission element in modern mechanical transmission systems, the performance of the synchronization belt is directly related ...Explore More -

How does the tooth design of synchronous timing belts affect its performance

Tooth design plays a vital role in the performance of synchronous belts, directly affecting their synchronization accuracy and transmission efficiency...Explore More

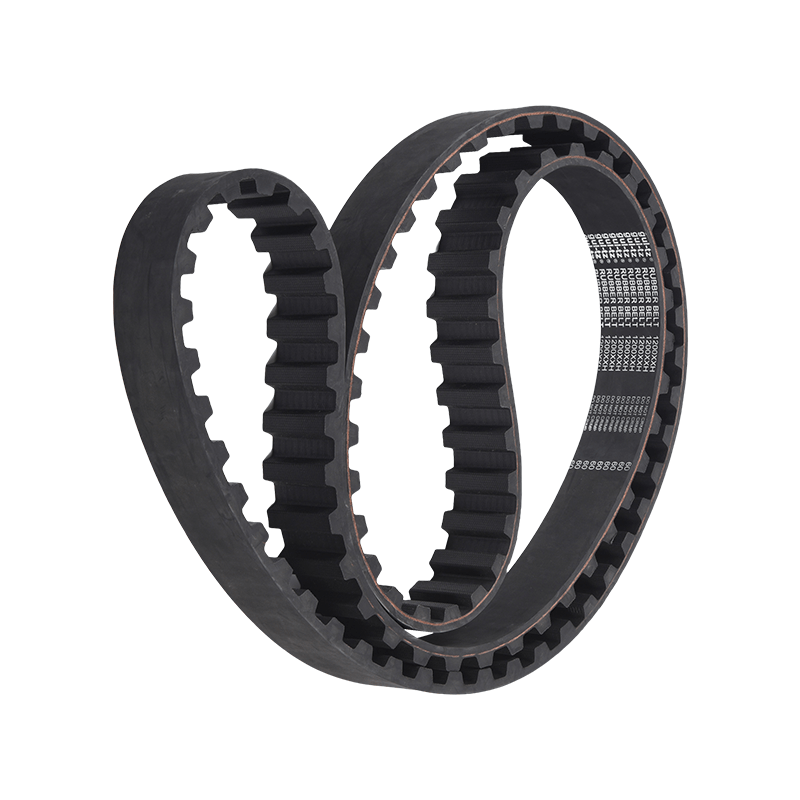

Industry knowledge about Double-Sided Timing Belts

Double-sided industrial timing belts play an important role in modern industrial transmission systems. Their unique design and excellent performance make them widely used in many industries. Since its establishment in 1992, Ningbo GUL TZ Rubber Belt Co., Ltd. has focused on the research and development and production of high-quality rubber timing belts, especially double-sided industrial timing belts. With its unique structural design, it has become a leader in the industry.

Core structure of double-sided design

The design concept of double-sided industrial timing belts is based on its double-sided tooth structure, which enables the belt to effectively transmit power in both directions. This design significantly improves transmission efficiency and achieves uniform load distribution during use, thereby extending service life. The basic structure of the double-sided design can be divided into the following key parts:

1. Tooth structure: The tooth design of the double-sided industrial timing belt is one of its core features. The depth, shape and spacing of the tooth are precisely calculated to ensure sufficient friction when in contact with the pulley, thereby achieving efficient power transmission. Usually, the tooth design adopts a trapezoidal or arc shape, which effectively reduces slipping and skidding and ensures stability under high load conditions.

2. Belt material: The belt body of the double-sided timing belt is generally made of high-strength synthetic rubber and contains reinforced fiber material. This material combination not only improves the tensile strength of the belt, but also enhances its wear resistance and heat resistance. Ningbo GUL TZ Rubber Belt Co., Ltd. focuses on combining high performance with environmental protection in material selection to ensure that each timing belt meets international standards.

3. Inner and outer layer design: The structure of the double-sided timing belt is usually composed of an inner layer and an outer layer. The inner layer is responsible for bearing tension, while the outer layer is subject to friction and wear. The reinforced fiber material of the inner layer provides the necessary strength and stability, and the rubber material of the outer layer provides good wear resistance and anti-aging ability. This inner and outer layer design enables the double-sided timing belt to maintain excellent performance in a high-intensity working environment.

Scientificity of tooth design

Tooth design is an important link in the structural design of double-sided industrial timing belts, and its scientificity directly affects the transmission efficiency and service life of the belt. The following are several key elements of the tooth design of double-sided timing belts:

Tooth depth and width: Accurate calculation of tooth depth and width is essential to ensure sufficient contact area during transmission. Too shallow teeth may lead to insufficient friction, while too deep teeth may increase belt wear. Therefore, a reasonable tooth design is the key to achieving efficient transmission.

Tooth angle: The angle design of the tooth shape affects the contact between the belt and the pulley. A reasonable tooth angle can effectively reduce slippage and improve the stability of power transmission. Usually, the tooth angle is set between 15° and 30°, and the design within this range takes into account both friction and wear.

Tooth arrangement: The tooth arrangement design of the double-sided industrial timing belt is also crucial. The tooth arrangement not only affects the flexibility and adaptability of the belt, but also the noise level and running smoothness of the belt. A reasonable tooth arrangement design can improve the overall performance of the belt and ensure stable operation under different working conditions.

Significant advantages of reinforced structure

The reinforced structural design of the double-sided industrial timing belt enables it to perform well in high-load and high-intensity environments. The specific advantages include:

Tensile strength: The reinforced structure of the double-sided timing belt significantly improves its tensile strength, enabling it to operate stably under high-load conditions. This feature has made the double-sided timing belt widely used in the fields of automobiles, machinery manufacturing, etc.

Wear resistance: The wear resistance of the double-sided timing belt has been significantly improved by selecting high-quality rubber and reinforcement materials. This feature allows it to maintain a low wear rate in a long-term, high-intensity working environment, thereby extending its service life.

Temperature resistance: The structural design of the double-sided industrial timing belt fully considers temperature resistance. High-quality materials and reasonable structural design enable the double-sided timing belt to work stably in a temperature range of -30°C to +100°C, adapting to the needs of various industrial environments.

English

English 简体中文

简体中文