About Us

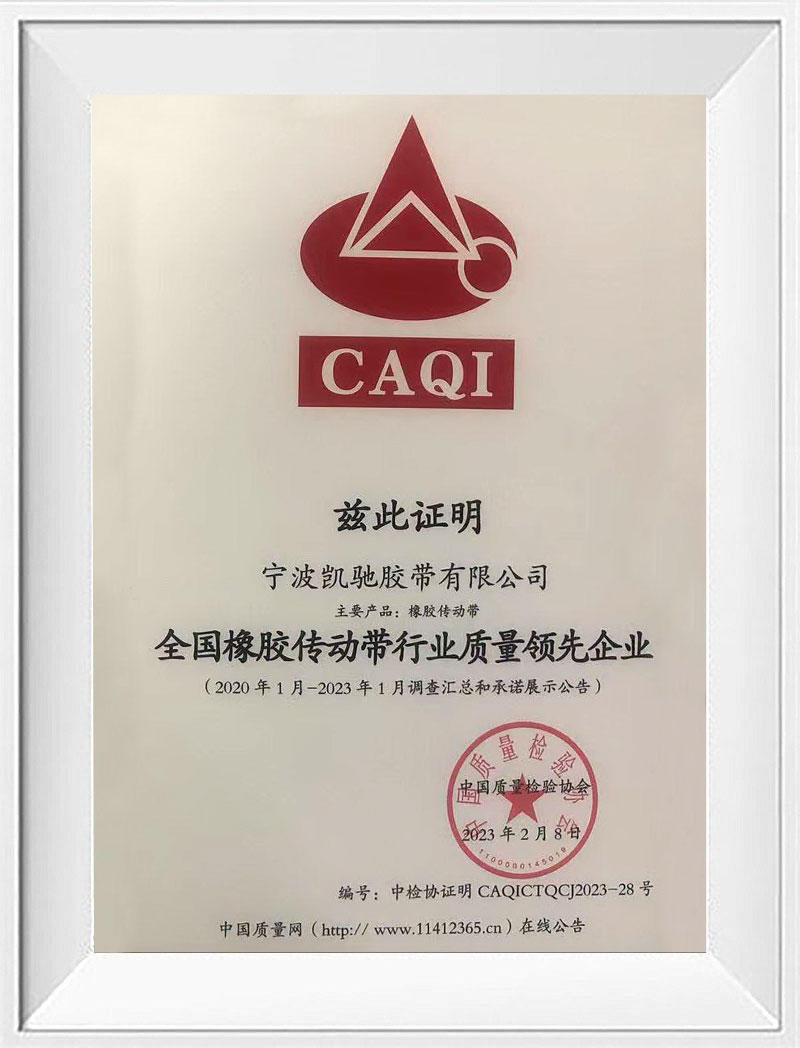

Honor

Pay attention to news News and Exhibitions

-

How does the installation angle of a ribbed belt affect its performance

As a transmission device commonly used for power transmission, ribbed belts are widely used in many fields such as industry, automobiles, and home app...Explore More -

How does the tensile strength of a ribbed belt affect its service life

Ribbed belts, as an important component in modern mechanical transmission systems, are widely used in automobiles, industrial equipment, household app...Explore More -

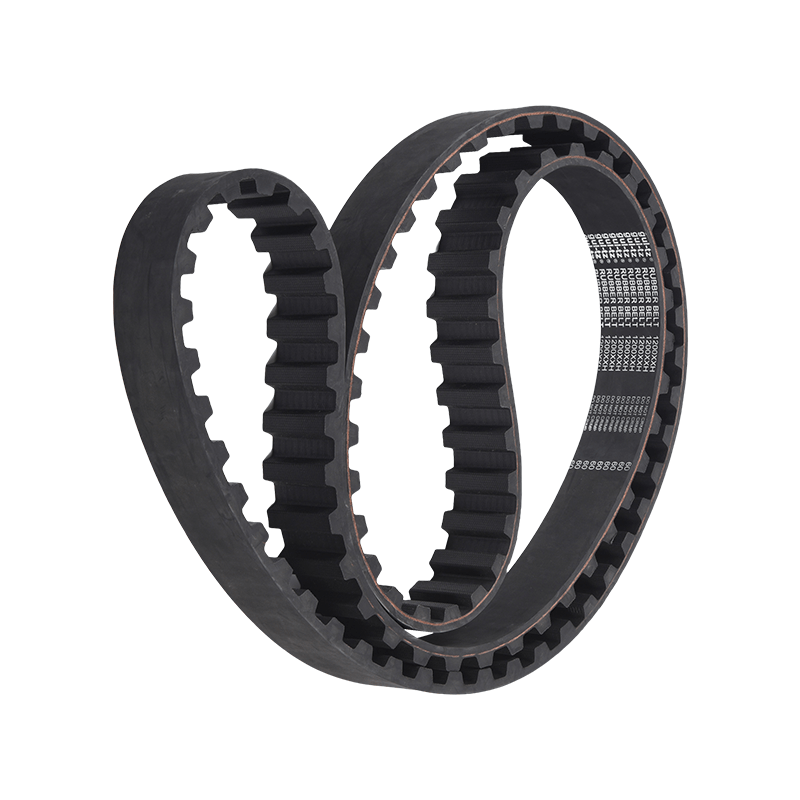

What are the advantages and disadvantages of arc-tooth synchronization belts compared with chain transmission

In mechanical transmission systems, arc-tooth synchronous belt and chain transmission are two common and important power transmission methods. The two...Explore More -

How much does the arc design of the synchronous belt tooth shape affect the meshing stability

As an important power transmission element in modern mechanical transmission systems, the performance of the synchronization belt is directly related ...Explore More -

How does the tooth design of synchronous timing belts affect its performance

Tooth design plays a vital role in the performance of synchronous belts, directly affecting their synchronization accuracy and transmission efficiency...Explore More

Industry knowledge about Flat Belts

Features of surface treatment of flat belts

In modern mechanical transmission systems, flat belts are key components, and the quality of their performance directly affects the operating efficiency and stability of the equipment. With the continuous advancement of industrial technology, the surface treatment technology of flat belts has been significantly developed and has become an effective means to improve their performance and applicability.

Optimization of friction performance

A notable feature of the surface treatment of flat belts is the improvement of friction performance. Friction is a key factor affecting transmission efficiency and load capacity. By applying a special coating to the surface of the flat belt, its friction coefficient can be significantly improved. This treatment not only effectively prevents slippage during high load or high-speed operation, but also ensures the stability of the transmission process. For example, Ningbo GUL TZ Rubber Belt Co., Ltd. applies advanced surface treatment technology to its flat belt products, which enables its products to show excellent friction performance in various industrial applications, especially in equipment with extremely high transmission accuracy requirements such as CNC machine tools and automated production lines.

Improvement of wear resistance and service life

Flat belts will gradually age due to friction and wear during long-term operation. Therefore, it is crucial to improve their wear resistance. By using wear-resistant materials as surface coatings, the service life of flat belts can be significantly extended and the replacement frequency due to wear can be reduced. In practical applications, wear-resistant coatings can effectively resist the erosion of flat belts by the external environment, especially in high-load and high-frequency operation occasions. This feature not only reduces maintenance costs, but also improves the overall operating efficiency of the equipment. Ningbo GUL TZ Rubber Belt Co., Ltd.'s products excel in this field and can meet the stringent requirements of different industries for wear resistance.

Enhanced chemical and environmental resistance

The surface treatment of flat belts also significantly improves their resistance to chemicals and environmental factors. In many industrial applications, flat belts are often exposed to harsh environments such as grease, chemical solvents and moisture. By special treatment of the surface of flat belts, their resistance to oil, water and chemical corrosion can be enhanced. In the food processing industry, flat belts need to withstand the erosion of grease and moisture. Flat belts with waterproof and oil-resistant coatings can effectively prevent contamination and ensure food safety. In addition, in the chemical and pharmaceutical industries, the chemical stability of flat belts is crucial to ensure the normal operation of equipment in harsh environments.

Improved anti-aging performance

The anti-aging performance of flat belts is also one of the important characteristics of surface treatment. Over time, rubber materials may age due to factors such as ultraviolet rays and ozone, resulting in performance degradation. By anti-aging treatment of the flat belt surface, this process can be effectively delayed and its service life can be extended.

What are the application areas of flat belts?

As a key component in mechanical transmission systems, flat belts are widely used in many industries. Due to their excellent transmission efficiency, flexible design and low maintenance costs, they have become the core components of many mechanical equipment. Since its establishment in 1992, Ningbo GUL TZ Rubber Belt Co., Ltd. has focused on the research and development and production of high-quality rubber transmission belts, covering a variety of types such as flat belts, V-belts and synchronous belts. With its excellent product quality and technical support, it serves many industries such as automobiles, food processing, textiles and automation equipment.

In the automotive industry, the application of flat belts is crucial, mainly used in the power transmission system of the engine. There are multiple components in the engine of modern cars that need to be powered by belts, such as water pumps, generators and air conditioning compressors. Flat belts can efficiently transmit the power of the engine to these components, thereby ensuring the normal operation of the vehicle. In view of the high temperature and high load working environment, automotive flat belts usually use high-performance wear-resistant materials and undergo special surface treatment to enhance their wear resistance and anti-aging properties. Ningbo GUL TZ Rubber Belt Co., Ltd.'s flat belt products have performed well in meeting the strict requirements of automobile manufacturers for high performance, becoming a reliable choice in the industry.

In the food processing industry, equipment reliability and hygiene standards are extremely important. Flat belts are mainly used in conveying and transmission systems in this field, and the equipment involved includes conveyor belts, cutting machines and packaging machines. The use of specially designed food-grade flat belts can effectively avoid food contamination during processing. In addition, the oil, water and cleaning resistance of flat belts are particularly important in food processing. Ningbo GUL TZ Rubber Belt Co., Ltd.'s flat belts are specially treated to effectively resist the erosion of grease and moisture, ensuring food safety and long-term stable operation of equipment.

The textile industry is also an important application area for flat belts. In this industry, flat belts are widely used in equipment such as looms, dyeing machines and sewing machines. Its stable working ability under high speed and high load conditions ensures production efficiency and product quality. Due to the complex working environment of the textile industry, flat belts need to have excellent wear resistance and antistatic properties. Ningbo GUL TZ Rubber Belt Co., Ltd. strictly controls material selection and surface treatment to ensure the reliability and durability of its products in the textile production process.

With the continuous advancement of industrial automation, the application of flat belts in automation equipment is becoming more and more extensive. Whether in material transportation on the production line or power transmission in the robot system, flat belts play an indispensable role. It can achieve efficient and stable transmission to ensure the normal operation of automation equipment. In automation equipment, the design of flat belts must fully consider their flexibility and adaptability. The flat belts produced by Ningbo GUL TZ Rubber Belt Co., Ltd. have good flexibility and can meet the needs of various complex working environments.

English

English 简体中文

简体中文