Ningbo GUL TZ Rubber Belt Co., Ltd.

Contact Us

Contact Us

About Us

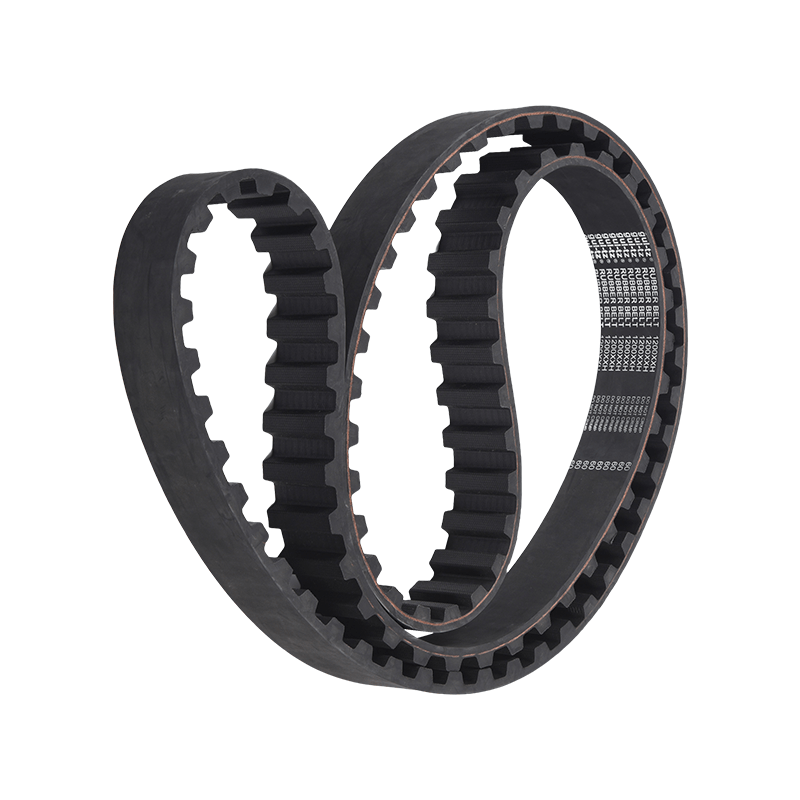

Ningbo GUL TZ Rubber Belt Co., Ltd. is China Thickened Industrial Timing Belts Suppliers and Thickened Industrial Timing Belts Company, the company was established in 1992, specializing in the production of rubber timing belts, V-ribbed belts, open belts and timing pulleys. The company now has the factory covering an area of 32,000 square meters and nearly 300 employees, with an annual output of 120 million pieces and an output value of 200 million yuan. We supply Thickened Industrial Timing Belts Custom, is a national high-tech enterprise, the drafting unit of national standards and industry standards, and has passed ISO9001, ISO14001 and ISO45001 system certification.

Play Video

Honor

See More

Pay attention to news News and Exhibitions

-

What are the effects of insufficient tension on synchronous timing belts

As an important power transmission component, sync...Explore More -

How to solve the sliding problem of multi-V belt

As an important part of industrial power transmiss...Explore More -

What are the main safety precautions when using multi-V belts

V-ribbed belts are widely used in industrial appli...Explore More -

What should be paid attention to in the maintenance of raw-edge v belts

Raw-edge V belts are a key transmission device tha...Explore More -

What are the structural advantages of raw-edge v belts

Raw-edge V belts are common transmission belts in ...Explore More

Industry knowledge about Thickened Timing Belts

Thickened industrial timing belts, also known as double-ply timing belts, are timing belts that are made with an additional layer of material to increase their thickness and strength. This additional layer can be made from a variety of materials, such as fabric, rubber, or plastic, and is added to the belt during the manufacturing process.

The main purpose of thickened industrial timing belts is to increase their load-carrying capacity and durability, making them ideal for applications that require high strength and resistance to wear and tear. The additional layer of material provides higher tensile strength and improved resistance to stretching and breaking.

The Advantages of Thickened Industrial Timing Belts

Thickened industrial timing belts are designed to transmit more power and operate at higher speeds than traditional timing belts. The added thickness of the belt allows for increased surface area contact with the pulleys, resulting in improved power transmission efficiency. This increased efficiency can lead to reduced energy consumption and lower operating costs.

In addition to improved efficiency, thickened timing belts also offer greater resistance to wear and tear. This means that they require less frequent maintenance and replacement, resulting in reduced downtime and increased productivity.

Increased Durability and Performance with Thickened Timing Belts

Thickened industrial timing belts are made from high-quality materials, such as neoprene, which offer superior resistance to abrasion and fatigue. This makes them more durable and long-lasting than traditional timing belts.

Furthermore, thickened timing belts are designed to withstand extreme temperatures and harsh environmental conditions. This makes them ideal for use in industries such as mining, oil and gas, and heavy manufacturing, where machinery is exposed to challenging operating conditions.

The Benefits of Choosing Thickened Timing Belts for Heavy-Duty Applications

Thickened timing belts are particularly well-suited for heavy-duty applications where machinery operates at high speeds and under heavy loads. The added thickness of the belt allows for greater power transmission, which is essential for the efficient operation of heavy machinery.

In addition, thickened timing belts are more resistant to stretch and elongation than traditional timing belts. This means that they are less likely to slip or lose their tension, resulting in more precise and accurate operation of machinery.

English

English 简体中文

简体中文