About Us

Honor

Pay attention to news News and Exhibitions

-

How does the installation angle of a ribbed belt affect its performance

As a transmission device commonly used for power transmission, ribbed belts are widely used in many fields such as industry, automobiles, and home app...Explore More -

How does the tensile strength of a ribbed belt affect its service life

Ribbed belts, as an important component in modern mechanical transmission systems, are widely used in automobiles, industrial equipment, household app...Explore More -

What are the advantages and disadvantages of arc-tooth synchronization belts compared with chain transmission

In mechanical transmission systems, arc-tooth synchronous belt and chain transmission are two common and important power transmission methods. The two...Explore More -

How much does the arc design of the synchronous belt tooth shape affect the meshing stability

As an important power transmission element in modern mechanical transmission systems, the performance of the synchronization belt is directly related ...Explore More -

How does the tooth design of synchronous timing belts affect its performance

Tooth design plays a vital role in the performance of synchronous belts, directly affecting their synchronization accuracy and transmission efficiency...Explore More

Industry knowledge about Rubber Driving Belt

What is the effect of the tension of rubber driving belt on its working performance?

Rubber driving belts play a vital role in modern mechanical transmission systems and are widely used in many fields such as automobiles, industrial equipment and household appliances. As a high-tech enterprise established in 1992, we focus on the production of rubber timing belts, V-belts, open belts and timing pulleys, and are committed to providing efficient and reliable transmission solutions. In the design and application of transmission belts, the management of tension is particularly important because it directly affects the working performance, service life and overall efficiency of the transmission belt.

The definition and importance of tension

Tension refers to the pulling force applied to the rubber driving belt during its operation. Appropriate tension ensures good contact between the belt and the pulley, thereby effectively transmitting power. Whether the tension is too low or too high, it will have an adverse effect on the performance of the belt. Therefore, when designing and using the belt, reasonable tension setting is crucial.

The impact of too low tension

When the tension of the rubber driving belt is insufficient, a series of problems may occur:

1. Slip phenomenon: Insufficient tension will cause the friction between the belt and the pulley to decrease, which will cause slippage. This will not only reduce the transmission efficiency, but also cause unstable power transmission and affect the normal operation of the equipment.

2. Increased wear: Slippage increases the friction between the belt surface and the pulley, which accelerates the wear of the belt. This wear not only shortens the service life of the belt, but may also cause equipment failure and increase maintenance costs.

3. Noise and vibration: Under low tension, the belt may generate abnormal noise and vibration during operation, further increasing the maintenance requirements of the equipment and may affect the comfort of the surrounding working environment.

Effects of excessive tension

Although proper tension is critical to the performance of the belt, excessive tension can also lead to a series of problems:

1. Belt damage: Excessive tension increases the load on the belt, causing accelerated material fatigue and even possible belt breakage. This situation not only causes production stagnation, but may also cause serious damage to the equipment.

2. Pulley wear: High tension not only affects the belt itself, but also causes additional wear on the pulley. Excessive wear of the pulley reduces the accuracy of its fit with the belt, further affecting the transmission efficiency.

3. Increased energy consumption: Excessive tension will cause additional energy loss and increase the energy consumption cost of the equipment. This is an issue that cannot be ignored for modern enterprises that pursue high efficiency and environmental protection.

Relationship between tension and transmission efficiency

There is a direct relationship between the tension of the transmission belt and its transmission efficiency. Appropriate tension can ensure good contact between the transmission belt and the pulley, thereby maximizing the power transmission efficiency. Studies have shown that the transmission efficiency of the transmission belt is largely proportional to its tension. Each type of rubber transmission belt has its optimal tension range, and exceeding this range will lead to reduced efficiency. Therefore, in practical applications, enterprises should choose the appropriate tension according to the specific load and application scenario.

Dynamic load adaptability

In some application scenarios, the equipment may experience dynamic load changes during operation, which requires the transmission belt to have good adaptability. By using high-performance rubber materials and optimized designs, the stability and durability of the transmission belt under dynamic loads can be improved, thereby meeting the needs of modern industry for efficient and reliable transmission systems.

How to correctly choose a rubber driving belt

Determination of application scenarios

In the process of selecting a rubber driving belt, it is crucial to clarify the application scenario. Different mechanical equipment and working environments have different performance requirements for transmission belts. In-depth understanding of specific application scenarios can help users choose the most suitable type of transmission belt. Load type is an important factor affecting the selection of transmission belts. For example, the difference between constant load and impact load will directly affect the wear resistance and tensile strength of the transmission belt. In applications with high impact loads, it is necessary to choose a transmission belt with higher wear resistance and tensile strength.

The working environment should not be ignored either. Environmental factors such as high temperature, high humidity, oil pollution and chemical corrosion will have a significant impact on the performance of the transmission belt. Therefore, when selecting a transmission belt, these factors must be considered comprehensively to ensure its reliability and stability in a specific environment.

Selection of transmission belt type

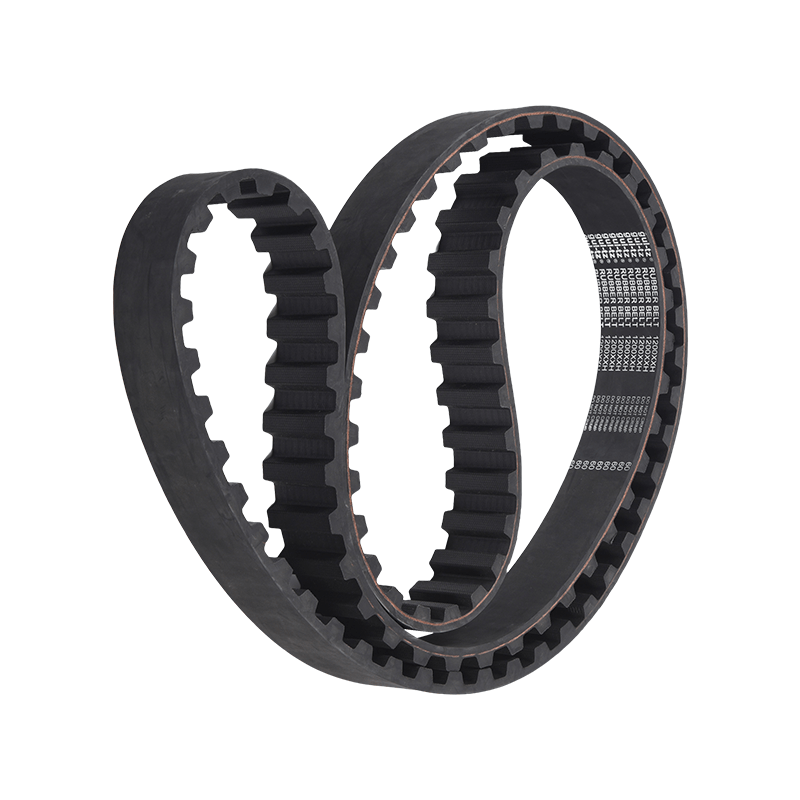

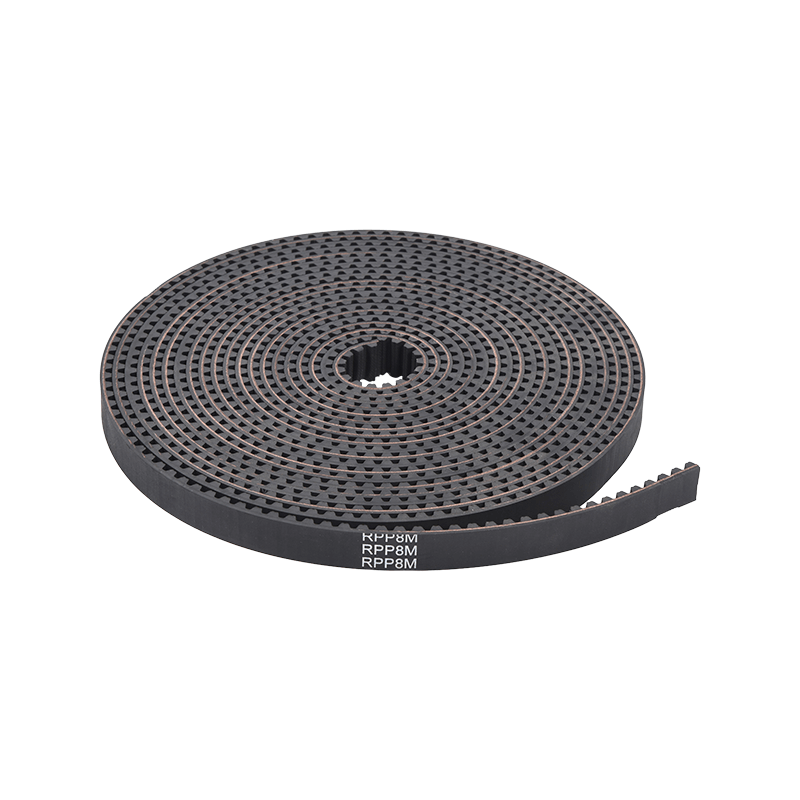

Rubber transmission belts are mainly divided into several types, including timing belts, V-belts and open belts. Each type of transmission belt exhibits unique performance advantages in specific applications. Timing belts are widely used in occasions that require precise synchronization, such as automotive engines and industrial machinery. Their excellent wear resistance and high strength make them suitable for high-load and high-speed working environments. V-belts are widely used in a variety of mechanical equipment due to their good adhesion, suitable for medium load and high speed transmission requirements. Open belts provide flexible configuration options, suitable for light load transmission, and show important functions in specific applications.

Consideration of size and specification

Choosing the right belt size and specification is key to ensuring the normal operation of the equipment. The length, width and thickness of the belt will affect its performance. The length of the belt needs to be accurately measured according to the actual needs of the equipment. A belt that is too long may cause slippage, while a belt that is too short will affect normal operation. Width and thickness are directly related to the load-bearing capacity of the belt. For high-load applications, it is necessary to choose a wider and thicker belt to ensure that it can withstand the corresponding workload.

Impact of material selection

The material selection of rubber belts directly affects its performance. The right material can significantly improve the wear resistance, oil resistance and heat resistance of the belt. Different types of rubber materials have their own unique properties. For example, chloroprene rubber (CR) is suitable for use in high temperature and oily environments due to its excellent oil and heat resistance, while polyurethane materials are suitable for high-load applications due to their high wear resistance. In some high-load or high-temperature applications, the introduction of reinforcement materials (such as fiber reinforcement) can further improve the strength and durability of the belt.

Understanding of transmission efficiency

Transmission efficiency is an important factor that must be considered when selecting a rubber belt. High-efficiency transmission belts can effectively reduce energy loss, thereby improving the performance of the overall system. The friction coefficient plays a key role in the interaction between the transmission belt and the pulley. Choosing materials with a higher friction coefficient can significantly improve transmission efficiency and reduce slippage. When designing a transmission system, comprehensively considering the coordination and coordination of various components and optimizing the design scheme can effectively improve transmission efficiency and ensure efficient operation of the system.

English

English 简体中文

简体中文