About Us

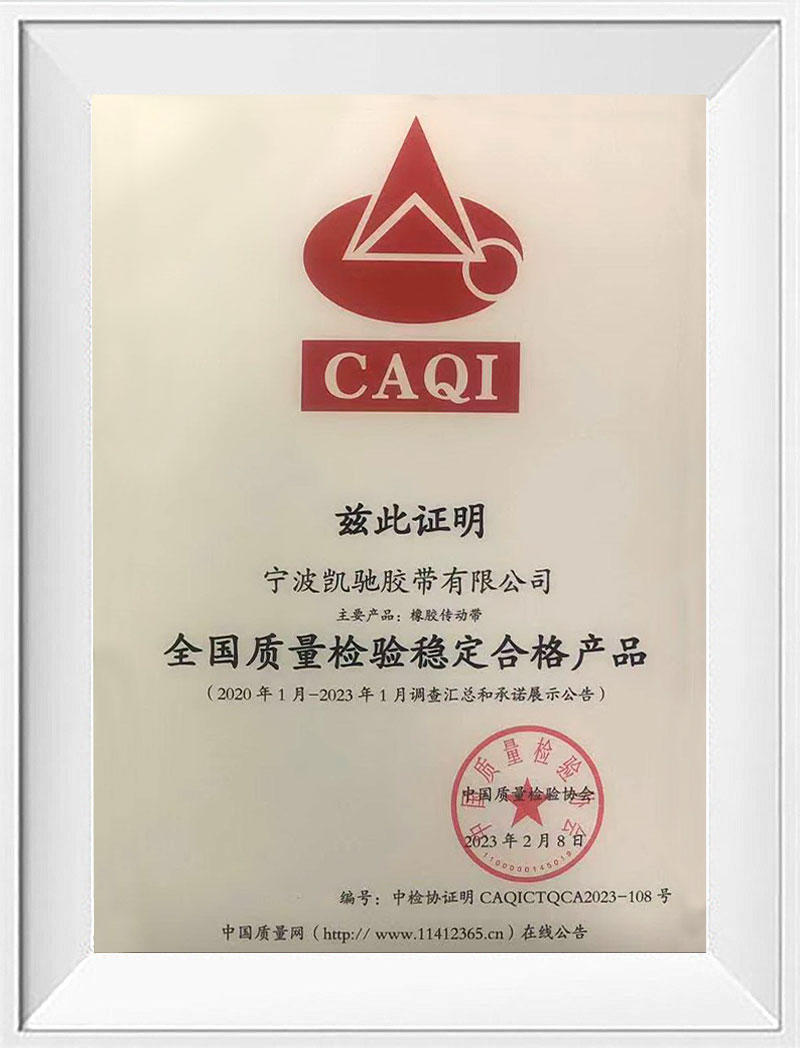

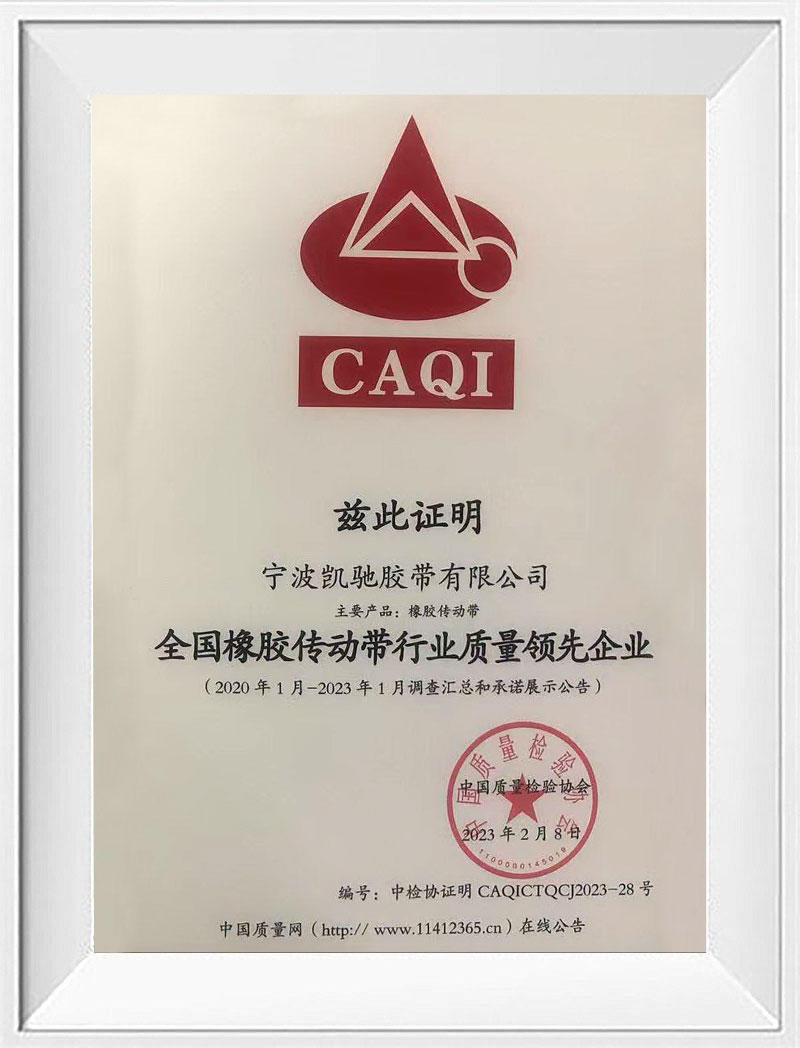

Honor

Pay attention to news News and Exhibitions

-

How does the installation angle of a ribbed belt affect its performance

As a transmission device commonly used for power transmission, ribbed belts are widely used in many fields such as industry, automobiles, and home app...Explore More -

How does the tensile strength of a ribbed belt affect its service life

Ribbed belts, as an important component in modern mechanical transmission systems, are widely used in automobiles, industrial equipment, household app...Explore More -

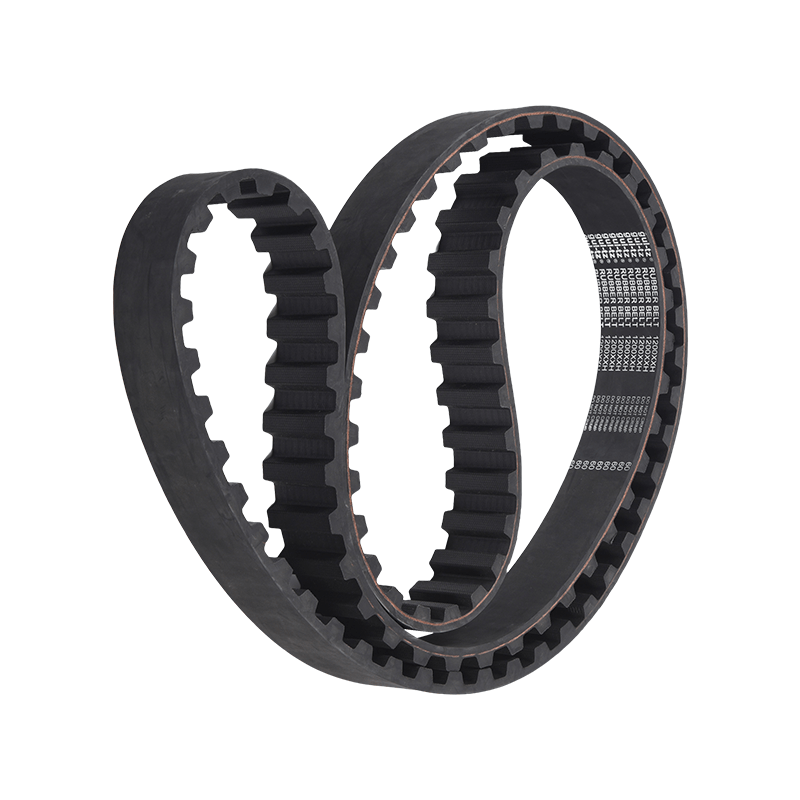

What are the advantages and disadvantages of arc-tooth synchronization belts compared with chain transmission

In mechanical transmission systems, arc-tooth synchronous belt and chain transmission are two common and important power transmission methods. The two...Explore More -

How much does the arc design of the synchronous belt tooth shape affect the meshing stability

As an important power transmission element in modern mechanical transmission systems, the performance of the synchronization belt is directly related ...Explore More -

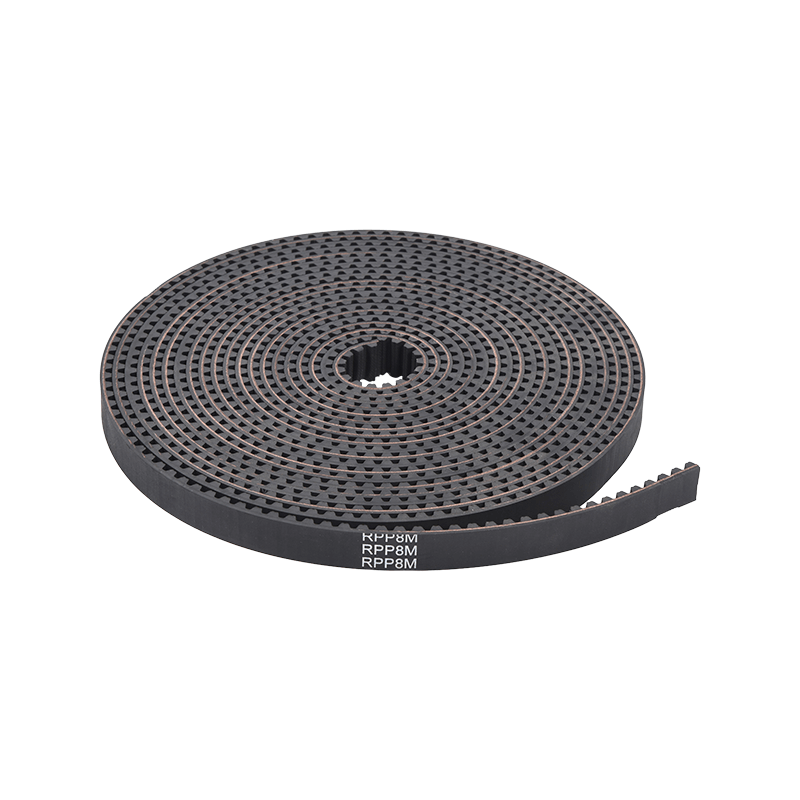

How does the tooth design of synchronous timing belts affect its performance

Tooth design plays a vital role in the performance of synchronous belts, directly affecting their synchronization accuracy and transmission efficiency...Explore More

Industry knowledge about Industrial Timing Belts

What factors are related to the power transmission of synchronous timing belts?

In today's mechanical transmission system, synchronous timing belts, as a key transmission element, are widely used in manufacturing, automation, automobiles and other industries with their excellent power transmission efficiency and precise operating characteristics. Since its establishment in 1992, our company has focused on the research and development and production of synchronous timing belts, and has accumulated rich industry experience and technical accumulation.

The importance of material selection

The material of synchronous timing belts is a key factor affecting their power transmission efficiency and service life. The combination of high-quality rubber materials and high-strength reinforcing fibers significantly improves the tensile strength and wear resistance of timing belts. The high-performance materials used by our company can effectively withstand large loads and maintain stable performance in harsh environments such as high temperature and high humidity. The choice of materials is not only related to the durability of the timing belt, but also directly affects its transmission efficiency. Therefore, during the design and production process, we strictly control the quality of materials to ensure that each timing belt can meet industry standards.

The core value of tooth shape design

Tooth shape design is one of the core elements of synchronous timing belts. The degree of tooth shape matching between timing belts and synchronous wheels directly affects the meshing effect. Reasonable tooth profile design can not only improve transmission efficiency, but also effectively reduce noise and vibration. Our company has introduced advanced CAD/CAM technology in tooth profile design to ensure that the tooth profile of each timing belt is accurately calculated and tested to achieve the best transmission effect. Scientific tooth profile design improves the stability of power transmission, reduces energy loss, and thus improves the efficiency of the overall system.

Influence of tension and installation accuracy

The tension of the synchronous timing belt is an important factor affecting its power transmission capacity. Too loose tension will cause the timing belt to slip and reduce transmission efficiency; while too tight tension may cause friction and wear, and accelerate the aging of the timing belt. During the installation process, the tension should be reasonably adjusted according to the actual operation of the equipment. In addition, installation accuracy is also crucial. Imprecise installation will lead to poor meshing between the timing belt and the synchronous wheel, thereby affecting the stability and efficiency of the transmission. Therefore, we provide professional guidance during the installation process to ensure that each timing belt can operate in the best condition.

Optimization of transmission ratio and load characteristics

The transmission ratio is the ratio of the speed between the input shaft and the output shaft, which directly affects the efficiency and characteristics of power transmission. When designing a transmission system, it is necessary to select a suitable transmission ratio according to specific application requirements to ensure the efficient operation of the system. Load characteristics should not be ignored either. The load fluctuations that the equipment bears during operation will directly affect the working state of the synchronous belt. In the design of our products, our company fully considers the performance of the timing belt under different load conditions to ensure that it can operate stably under various working conditions and meet the diverse needs of customers.

Improvement of environmental adaptability

Environmental factors have a significant impact on the performance of synchronous belts, including temperature, humidity, oil pollution and chemical corrosion. To meet these challenges, our company's synchronous belts have been specially treated to have good oil resistance and chemical resistance, and can work normally in a variety of harsh environments. In addition, the operating temperature range of the timing belt is wide, and it can maintain stable performance in an environment of -30℃ to +100℃. This excellent adaptability enables our synchronous belts to demonstrate excellent power transmission capabilities in different industries and application scenarios.

Design features of synchronous timing belts

In modern mechanical transmission systems, synchronous belts have become an important part of industrial automation and mechanical transmission with their excellent performance and wide application. The high standards of its design and materials make the synchronous timing belt perform well in a variety of industrial environments and meet the stringent requirements of different industries for transmission systems.

Precision of tooth shape design

The tooth shape design of the synchronous timing belt is one of its core features. Compared with traditional belt transmission, the tooth shape of the synchronous timing belt and the tooth shape of the synchronous wheel are precisely meshed, which ensures the high efficiency of power transmission. Our company uses advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technology to optimize the tooth shape to improve transmission efficiency and reduce noise. Through precise design, the timing belt can significantly reduce sliding and wear, and maintain stable transmission performance even under high load conditions.

Scientific material selection

The selection of materials has a direct impact on the performance and service life of the synchronous timing belt. Our company selects high-quality rubber materials and combines them with high-strength reinforcing fibers to ensure the stability and durability of the timing belt in high temperature, high humidity and high load environments. These high-performance materials not only improve the tensile strength and wear resistance of the timing belt, but also effectively resist oil pollution and chemical corrosion, and can adapt to the needs of various industrial application environments.

Reasonable tensioning structure

The design of the tensioning structure is a key factor in ensuring the normal operation of the synchronous timing belt. Reasonable tension can effectively prevent the timing belt from slipping and wearing, thus ensuring the high efficiency of power transmission. Our company fully considers the tension requirements of different equipment during the design process and provides a variety of tensioning methods for customers to choose from. Whether it is automatic tensioning or manual tensioning, our design can ensure that the timing belt remains in the best condition during operation, thereby improving the efficiency of the entire system.

Wide range of temperature adaptability

The temperature adaptability of synchronous timing belts is an important feature in their design. Our products can work stably in the temperature range of -30℃ to +100℃ and adapt to various extreme environments. This wide temperature adaptability makes synchronous timing belts perform well in a variety of applications such as cooling systems and heat treatment equipment, ensuring the reliability and safety of equipment.

Advantages of low noise and low vibration

In the design of synchronous timing belts, we pay special attention to the noise and vibration levels during their operation. By optimizing the tooth shape design and material selection, the product can effectively reduce noise and vibration during operation. This low noise feature not only improves the comfort of the working environment of the equipment, but also reduces the fatigue of mechanical components, thereby extending the service life of the equipment. In situations where there are strict requirements on noise, such as medical equipment and laboratory instruments, the use of synchronous timing belts can significantly improve the user experience.

Flexible custom design capabilities

Our company knows that each customer's needs are unique, so we provide flexible customization options in the design of synchronous timing belts. Whether it is special size, special material, or specific tooth design, we can adjust it according to the specific needs of customers. This flexibility allows our products to adapt to the performance requirements of different mechanical equipment, ensuring customer satisfaction and efficiency in actual applications.

English

English 简体中文

简体中文