About Us

Honor

Pay attention to news News and Exhibitions

-

How does the installation angle of a ribbed belt affect its performance

As a transmission device commonly used for power transmission, ribbed belts are widely used in many fields such as industry, automobiles, and home app...Explore More -

How does the tensile strength of a ribbed belt affect its service life

Ribbed belts, as an important component in modern mechanical transmission systems, are widely used in automobiles, industrial equipment, household app...Explore More -

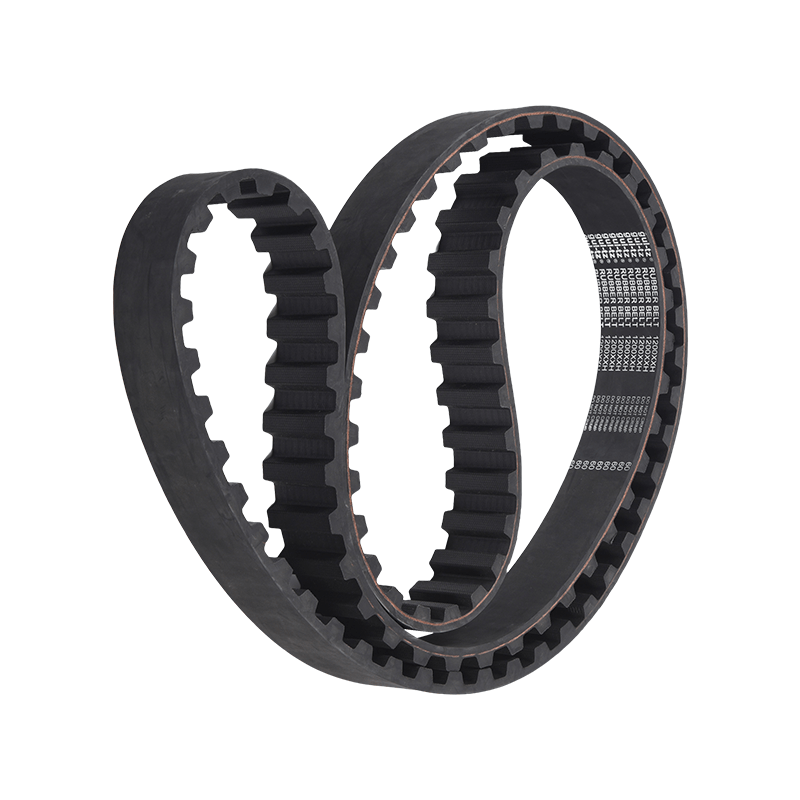

What are the advantages and disadvantages of arc-tooth synchronization belts compared with chain transmission

In mechanical transmission systems, arc-tooth synchronous belt and chain transmission are two common and important power transmission methods. The two...Explore More -

How much does the arc design of the synchronous belt tooth shape affect the meshing stability

As an important power transmission element in modern mechanical transmission systems, the performance of the synchronization belt is directly related ...Explore More -

How does the tooth design of synchronous timing belts affect its performance

Tooth design plays a vital role in the performance of synchronous belts, directly affecting their synchronization accuracy and transmission efficiency...Explore More

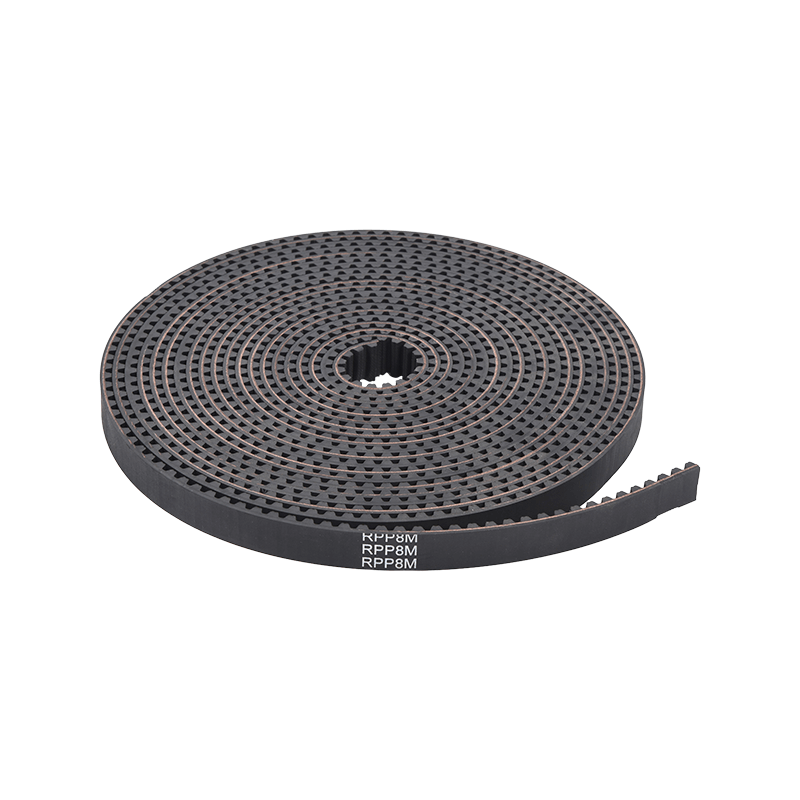

Industry knowledge about Open-ended Timing Belts

Open-ended Industrial Timing Belts play a vital role in modern manufacturing, and their application range covers automation equipment, conveyor systems, textile machinery and other fields. As an efficient power transmission component, the performance of Open-ended Industrial Timing Belts directly affects the operating efficiency and production cost of the equipment. However, in actual applications, timing belts may face a variety of faults that affect their normal operation. Since its establishment in 1992, Ningbo GUL TZ Rubber Belt Co., Ltd. has been committed to the research and development and production of rubber timing belts. It has accumulated rich industry experience and can provide customers with high-quality products and solutions.

Common Fault Types

Wear

Wear is one of the most common faults of Open-ended Industrial Timing Belts. As the equipment runs for a long time, the surface of the timing belt will gradually wear due to friction, resulting in a decrease in transmission efficiency and even possible belt breakage. The main causes of wear include:

Improper tension: Excessive tension will accelerate wear, while too little tension may cause slippage.

Poor pulley alignment: If the pulleys are not properly aligned, the timing belt will generate additional friction during operation, thereby accelerating wear.

Environmental factors: Harsh environmental conditions such as high temperature, high humidity or chemical corrosion can also significantly accelerate the wear of the timing belt.

Slipping

Slipping refers to the failure of the timing belt to effectively transmit power during operation, resulting in the failure of the equipment to operate normally. The reasons for this phenomenon are usually:

Insufficient tension: Improper adjustment of the tension of the timing belt may cause slipping.

Wear of the pulley: Wear or damage to the pulley surface will affect the grip of the timing belt, causing slipping.

Overload: Overloaded operation of the equipment may also cause the timing belt to slip, affecting overall production efficiency.

Cracks

Open-ended timing belts may crack over time. The formation of cracks is mainly related to the following factors:

Aging: Long-term exposure to high temperatures or sunlight will gradually age the material of the timing belt, causing cracks.

Chemical corrosion: Contact with grease, chemicals or other corrosive substances may cause the deterioration of the timing belt material, resulting in cracks.

Improper installation: Excessive force or failure to align correctly during installation may also cause cracks.

Deformation

Open-ended Industrial Timing Belts sometimes deform during use. Deformation is usually caused by the following reasons:

Overload operation: When the equipment is running under overload, the timing belt will be subjected to excessive pressure, resulting in deformation.

Temperature change: drastic temperature changes will cause thermal expansion or contraction of the timing belt material, which will lead to deformation.

Uneven wear: If the pulley is unbalanced or the tension of the timing belt is unevenly distributed, it will cause uneven wear of the timing belt during operation, eventually leading to deformation.

Fault detection and solution

Detection and solution of wear

Wear is one of the common faults of the timing belt. Its detection method includes regular inspection of the timing belt surface, especially observing whether there are obvious wear marks or cracks. If the wear is found to be more serious, it is recommended to replace the timing belt in time. At the same time, the tension and pulley alignment should be checked to ensure that the equipment is running in the best condition. During maintenance, reasonable tension adjustment and pulley alignment can effectively extend the service life of the timing belt.

Detection and solution of slippage

Slippage is usually manifested as poor power transmission, and the equipment may be accompanied by abnormal noise during operation. During detection, it is necessary to closely observe the operating status of the equipment. If slippage is found, the tension of the timing belt should be adjusted immediately to ensure that it is in the appropriate range. At the same time, the wear of the pulley needs to be checked and replaced if necessary to ensure the reliability of power transmission.

Detection and solution of cracks

The cracks of the timing belt usually appear at the edges and seams, so it is important to check these parts regularly. If cracks are found, the timing belt must be replaced in time, and the working environment must be checked to avoid the timing belt from contacting chemicals or being in a high temperature environment. These factors may accelerate the aging and damage of the material.

Detection and solution of deformation

The shape change of the timing belt will also affect its performance. During the inspection, it is necessary to observe whether there is obvious distortion or deformation. If deformation is found, the load of the equipment should be adjusted to ensure that it operates within the rated load range. At the same time, check the balance of the pulley and adjust it if necessary to reduce the impact of deformation on the timing belt.

English

English 简体中文

简体中文