Ningbo GUL TZ Rubber Belt Co., Ltd.

Contact Us

Contact Us

About Us

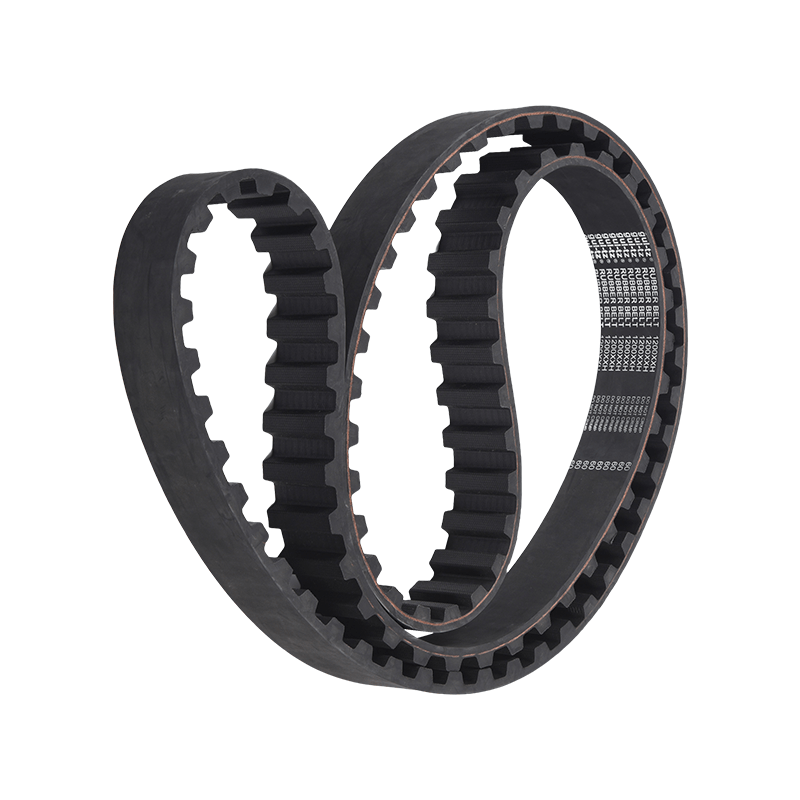

Ningbo GUL TZ Rubber Belt Co., Ltd. is China V-Ribbed Belts Suppliers and V-Ribbed Belts Company, the company was established in 1992, specializing in the production of rubber timing belts, V-ribbed belts, open belts and timing pulleys. The company now has the factory covering an area of 32,000 square meters and nearly 300 employees, with an annual output of 120 million pieces and an output value of 200 million yuan. We supply V-Ribbed Belts Custom, is a national high-tech enterprise, the drafting unit of national standards and industry standards, and has passed ISO9001, ISO14001 and ISO45001 system certification.

Play Video

Honor

See More

Pay attention to news News and Exhibitions

-

What are the effects of insufficient tension on synchronous timing belts

As an important power transmission component, sync...Explore More -

How to solve the sliding problem of multi-V belt

As an important part of industrial power transmiss...Explore More -

What are the main safety precautions when using multi-V belts

V-ribbed belts are widely used in industrial appli...Explore More -

What should be paid attention to in the maintenance of raw-edge v belts

Raw-edge V belts are a key transmission device tha...Explore More -

What are the structural advantages of raw-edge v belts

Raw-edge V belts are common transmission belts in ...Explore More

Industry knowledge about V-Ribbed Belts

V-ribbed belts, also known as multi-rib belts or serpentine belts, are a type of power transmission belt used in many automotive and industrial applications. They are made of a combination of rubber and synthetic materials and are designed with a V-shaped cross-section that allows them to provide reliable power transmission with reduced slippage and noise.

Characteristics of V-Ribbed Belts

V-ribbed belts are designed with a V-shaped cross-section that provides increased surface area compared to traditional flat belts. The ribs on the belt allow for better grip and increased power transmission, even in high-torque applications. The V-shaped design also allows for improved flexibility, allowing the belt to wrap around smaller pulleys and bend around corners without the risk of the belt slipping off the pulleys.

Advantages of V-Ribbed Belts

V-ribbed belts offer several advantages over traditional flat belts, including:

Reduced Slippage: V-ribbed belts provide increased grip and reduced slippage, even in high-torque applications. This allows for more efficient power transmission and better performance.

Reduced Noise: V-ribbed belts operate with less noise than traditional flat belts, thanks to their V-shaped design, which reduces vibration and noise.

Improved Efficiency: The improved grip and reduced slippage of V-ribbed belts allow for improved efficiency, which can lead to increased fuel economy and reduced emissions in automotive applications.

Longer Lifespan: The improved grip and reduced slippage of V-ribbed belts also lead to a longer lifespan than traditional flat belts. They are less likely to stretch or wear, which reduces the need for frequent maintenance and replacement.

Applications of V-Ribbed Belts

V-ribbed belts are commonly used in a wide range of automotive and industrial applications, including:

Automotive: V-ribbed belts are used in automotive engines to power accessories such as an alternator, air conditioning compressors, and power steering pumps.

Industrial: V-ribbed belts are used in many industrial applications, including conveyor systems, packaging machinery, and power transmission equipment.

HVAC: V-ribbed belts are used in HVAC systems to power fans and blowers.

Lawn and Garden: V-ribbed belts are used in lawn and garden equipment, such as lawnmowers and snow blowers.

English

English 简体中文

简体中文