The features and benefits of open timing belts

An open timing belt is a crucial component of the engine's timing system, responsible for synchronizing the rotation of the crankshaft and the camshaft(s). This article explores the features and benefits of open timing belts, highlighting their role in ensuring precise valve timing, reliable engine performance, and longevity. With their robust construction, efficient power transmission, and low noise operation, open timing belts offer a reliable and efficient solution for maintaining proper engine timing in a variety of applications.

Accurate Valve Timing and Engine Performance:

Open timing belts play a vital role in maintaining accurate valve timing, which is crucial for proper engine performance. These belts feature precisely spaced teeth that engage with the corresponding teeth on the camshaft and crankshaft sprockets, ensuring the synchronized rotation of these components. By accurately controlling the opening and closing of the engine's valves, the open timing belt optimizes combustion efficiency, power output, and fuel consumption. This results in improved engine performance, smoother operation, and reduced emissions.

Reliable Power Transmission and Durability:

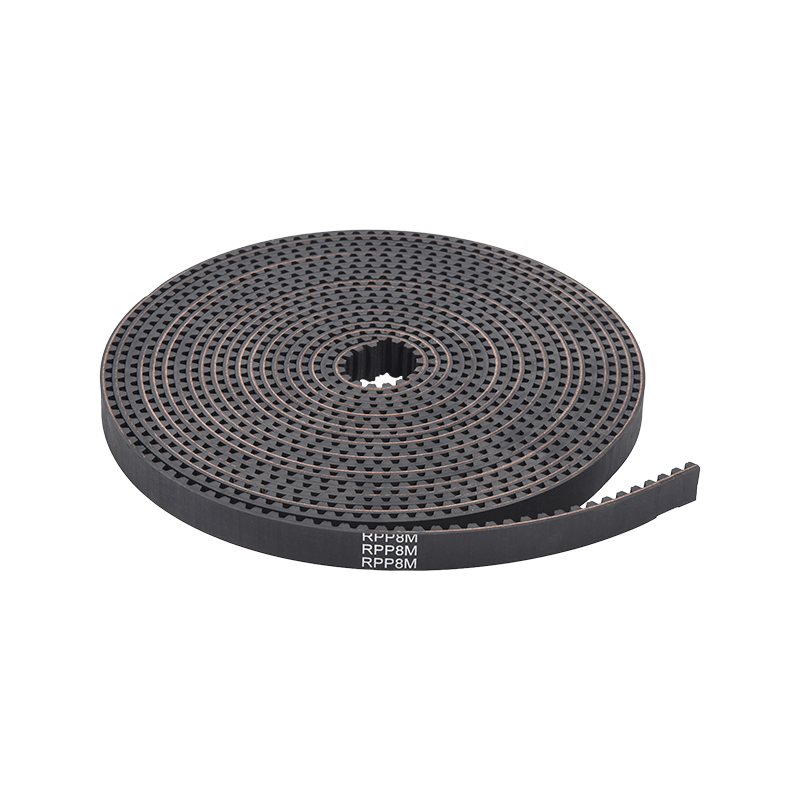

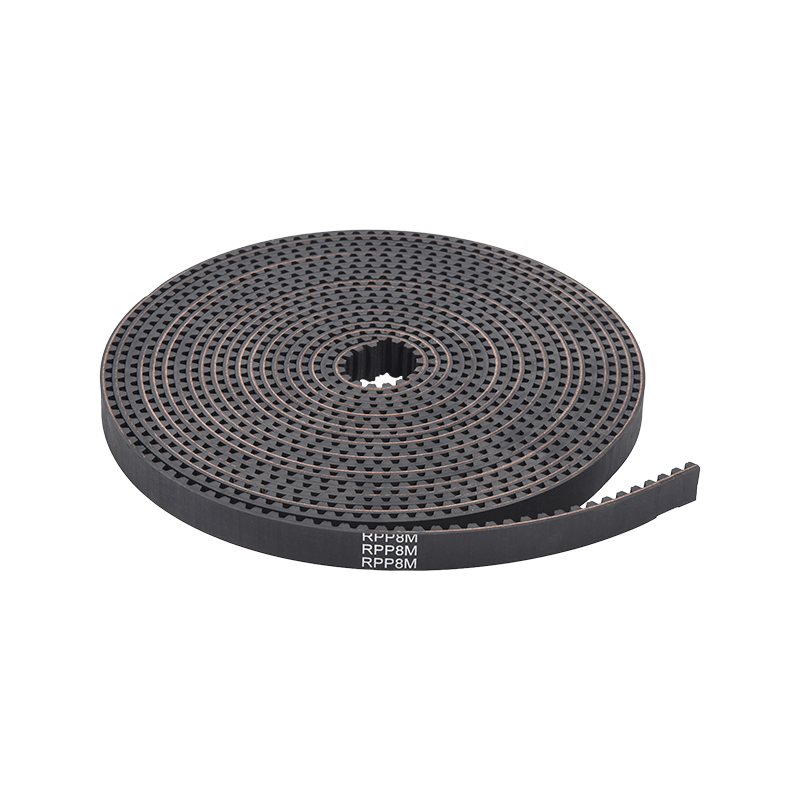

Open timing belts are engineered to provide reliable power transmission between the crankshaft and camshaft(s) without slippage. The belt's toothed design ensures a positive engagement with the sprockets, transmitting rotational force with minimal energy loss. This efficient power transfer helps maximize engine output and efficiency.

Furthermore, open timing belts are constructed using durable materials, such as high-strength rubber compounds reinforced with fiberglass or aramid cords. These materials offer excellent resistance to wear, heat, and fatigue, ensuring the belt's longevity and reliability under demanding operating conditions. Regular inspections and maintenance, including timely belt replacements as recommended by the manufacturer, contribute to the continued reliability and performance of the timing system.

Low Noise Operation and Reduced Maintenance:

Open timing belts are designed to operate with minimal noise and vibration, contributing to a quieter and more comfortable driving experience. The toothed design of the belt reduces slippage and eliminates the need for tensioners or idler pulleys, resulting in quieter operation compared to alternative timing systems.

Additionally, open timing belts require relatively low maintenance. Unlike timing chains that may require lubrication or periodic tension adjustments, open timing belts typically do not require routine maintenance beyond regular inspections.

Open-ended Timing Belts was developed in response to recent industrial needs for automation and energy conservation in equipment and production processes, typically used in linear motion drives.

There are two types of Long-Span Timing Belts : open-ended belts, which are mainly used for reciprocating motion, and endless belts, which can be used for rotational motion.

Hot Products

-

View More

View More

-

View More

View More

V-belt For Industry

-

View More

View More

T Type Industry Rubber Synchronous Belt

-

View More

View More

Toothed wedge belt

-

View More

View More

Thickened timing belt

-

View More

View More

Open Timing Belt

-

View More

View More

Automotive V-belt

-

View More

View More

Rubber Flat Belt

-

View More

View More

Ribbed Belt

-

View More

View More

Synchronous Pulley

-

View More

View More

Arc tooth industrial rubber synchronous belt

-

View More

View More

Automotive timing belt

English

English 简体中文

简体中文